Case Study: Shell Liner Special Emergency Care 26'x44.5' Ball Mill Feed Ring

Case study

In the operation of a concentrator plant in Chile, a 26'x44.5' ball mill that had steel linings had already worn the liners in the first two rings of the cylinder (feed side), so it was necessary to perform the maintenance of the ball mill. A shutdown was soon scheduled to change these liners.

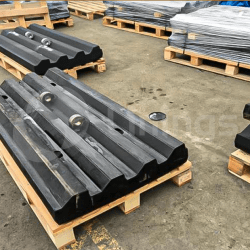

This request came to us and we immediately elaborated a design that would respond to the operational requirements of the ball mill. The proposal we worked on was Polywear SL composite shell liners in a double wave design, which we attended to in 3 weeks.

The client's expected duration was 7 months , however, the composite mill liners were withdrawn after 9 months , with the possibility of extending their duration for a few more months, as recorded in the measurements.

In this way we were able to meet the urgent need of this client in a very short period of time for manufacturing and, likewise, we exceeded the expectations of duration compared to steel liners.

Blog